Gear module is an essential concept in mechanical engineering, playing a crucial role in the design and operation of various gear systems. Essentially, the gear module determines the size and dimensions of the gear teeth. By understanding what gear module is and how it impacts gear design, engineers can optimize performance and efficiency in machinery. This article delves into the intricacies of gear module, exploring its significance and practical applications in the realm of mechanical engineering. Join us as we unravel the complexities of gear module to enhance your understanding of this fundamental engineering principle.

Exploring the World of Gear Module

Welcome, curious minds, to our exploration of the fascinating topic of gear module! Gear module can seem like a complex concept, but fear not; we will break it down into bite-sized pieces to help you understand it better. So, what exactly is gear module? Let’s dive in!

Understanding Gears

Before we delve into gear module, let’s talk about gears themselves. Gears are mechanical devices with teeth that mesh with other gears to transmit motion and power. They are like puzzle pieces that fit together to make things move.

Imagine a bicycle – the gears on a bike help you pedal smoothly and climb hills with ease. Gears can be found in various machines, from clocks to cars, making them essential components in many everyday items.

What is Gear Module?

Now, let’s get to the heart of the matter – gear module. In simple terms, gear module refers to the size of the gear teeth. Each gear has a specific size for its teeth, which is crucial for ensuring the gears mesh correctly and transmit motion efficiently.

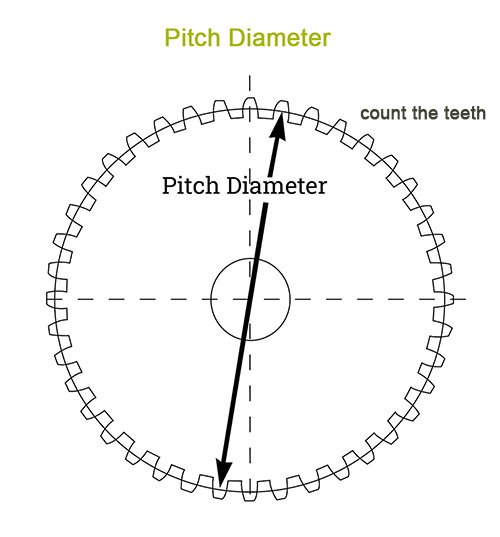

The gear module is determined by the pitch circle diameter of the gear and the number of teeth it has. It helps standardize gear sizes so that gears from different manufacturers can work together seamlessly.

Calculating Gear Module

To calculate the gear module, you need to know the pitch circle diameter (the theoretical circle where the gear tooth profile would mesh perfectly), and the number of teeth on the gear. By dividing the pitch circle diameter by the number of teeth, you can determine the gear module.

For example, if a gear has a pitch circle diameter of 40 mm and 10 teeth, the gear module would be 40 mm / 10 = 4 mm. This means that each tooth on the gear is spaced 4 mm apart.

Types of Gear Module

There are different types of gear modules used in various applications. The most common ones include:

- Normal Module: This is the standard gear module used in most applications.

- Circular Pitch Module: This module is used in specialized gear designs where tooth size is critical.

- Diametral Pitch Module: This module is commonly used in the United States and is based on the number of teeth per inch of the gear’s pitch diameter.

Applications of Gear Module

Gear module plays a crucial role in various industries and applications. From automotive transmissions to industrial machinery, gear module is essential for ensuring smooth and efficient gear operation. Different gear modules are used based on the requirements of the specific application.

For example, in high-speed applications, a smaller gear module may be preferred to reduce friction and wear. On the other hand, in heavy-duty applications, a larger gear module may be chosen for increased durability.

Importance of Gear Module

So, why is gear module so important? Well, imagine if gears of different sizes couldn’t work together – machines would grind to a halt! Gear module ensures that gears of varying sizes from different manufacturers can mesh seamlessly, allowing for the smooth transmission of motion and power.

By standardizing gear sizes through gear module, manufacturers can design and build machines with interchangeable parts, making maintenance and repairs easier and more cost-effective.

In conclusion, gear module is a crucial aspect of gear design and manufacturing. By understanding the size of gear teeth and how they interact with each other, engineers and designers can create efficient and reliable machines that power our world.

Next time you see gears turning in a machine, remember the role of gear module in making it all possible. We hope this journey into the world of gear module has piqued your interest and expanded your understanding of this essential mechanical concept. Stay curious!

Gear "Module" Explained in 1 Minute

Frequently Asked Questions

What is gear module?

Gear module refers to the ratio between the pitch circle diameter of a gear and the number of teeth it has. It is a critical parameter in gear design and manufacturing, representing the size of the gear teeth in relation to the gear itself.

How is gear module calculated?

Gear module is calculated by dividing the pitch circle diameter of the gear by the number of teeth it has. This calculation results in a unit of measurement that helps standardize gear sizes and tooth profiles in gear manufacturing.

What is the significance of gear module in gearing systems?

The gear module plays a crucial role in determining the size, strength, and compatibility of gears within a gearing system. Gears with matching modules are designed to work together efficiently, ensuring proper transmission of motion and power.

How does gear module affect gear tooth strength?

The gear module directly influences the size and spacing of gear teeth, affecting the strength and durability of the gear. A larger gear module typically results in stronger teeth, capable of withstanding higher loads and torque.

Final Thoughts

In conclusion, the gear module refers to the standardized unit for measuring the size of gears. It is a critical parameter in gear design and plays a vital role in ensuring proper gear meshing. Understanding what the gear module is helps engineers in selecting compatible gear sizes for optimal performance. Choosing the right gear module is essential for achieving desired gear ratios and ensuring efficient power transmission. Remember, the gear module is a key factor in designing any gear system.

home depot coupons moving helping customers save on essential home supplies

home depot coupons moving helping customers save on essential home supplies